The Pro 3 has been designed and manufactured to offer the highest possible price / performance ratio in its class with dedicated features that ensure minimal downtime and optimal performance as well as high quality parts.

Design Facts about the Felix Pro 3

Build Volume, 237 x 244 x 235 mm

High accuracy due to rigid frame, Within 0.1mm tolerance

Durable due to High quality materials.

Industrial grade plastics (POM)

Upgradable modular design, keep up with technology with low cost of ownership

High accuracy due to rigid frame, Within 0.1mm tolerance

Durable due to High quality materials.

Industrial grade plastics (POM)

Upgradable modular design, keep up with technology with low cost of ownership

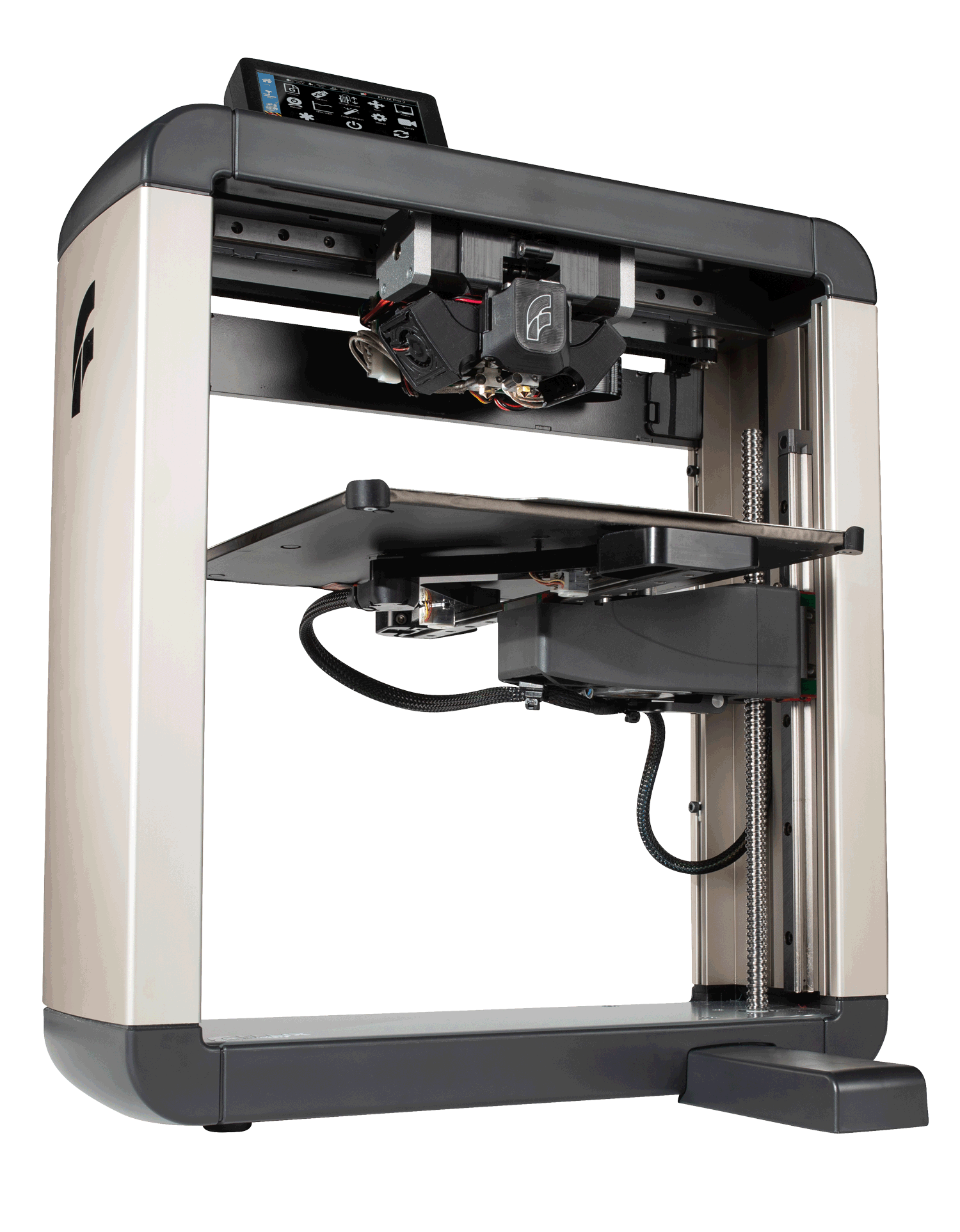

Open design – Easy Access

The FELIX Pro 2 has an open structure, giving you the joy to see your prints come to life with the least amount of obstructions. The innovative design of the FELIX Pro 2 has easy access so you can remove the build plate and the hot ends in just a few seconds.

High Precision- rigid frame

Enabling high precision prints, starts with a rigid frame. The FELIX Pro 3 is built from custom designed anodized aluminium extruded profiles from the 6000 series, this is the same aluminium used in aerospace and military designs. Next to that we use powder coated steel frame parts to make the frame as rigid as possible. The frame itself is also a part of the exterior design, making the design as efficient as possible.

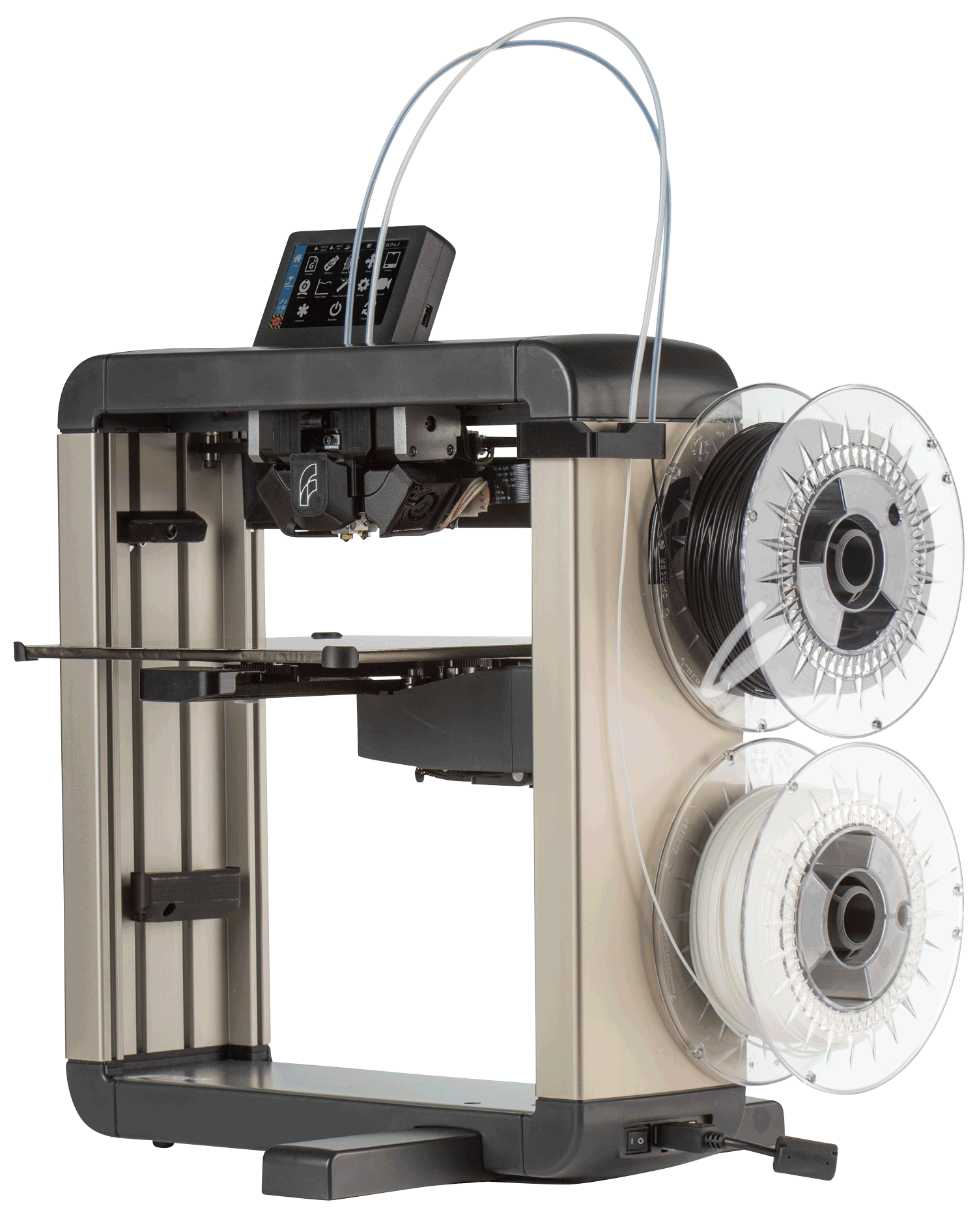

Upgradable by Design

All FELIXprinters are engineered in a modular way, it is part of the FELIX DNA. Upgrade your machine to ensure the latest technology. Using this design philosophy, performing maintenance on the FELIX pro series is easy.