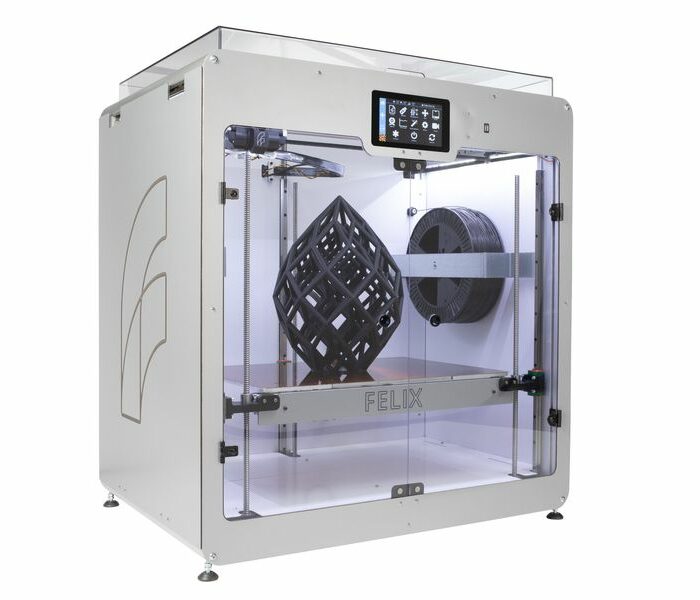

FELIX Pro L / XL

The FELIX Pro L and XL

Print up to 4x the buildvolume of most desktop printers reliably

The FELIX Pro L and XL are industrial additive manufacturing printers from FELIXprinters. This series provides a large build volume capacity, ideal to 3D print bigger parts.

These additive manufacturing systems have been designed to perform at scale, and both have been constructed to ensure reliable output for much larger parts.

The engineers at FELIXprinters fully understand the rigorous demands that are placed on an additive manufacturing machine when printing parts. Reliability and trust are the two main components when it comes to 3D printing larger parts. Larger parts equal longer prints. Start your print with the peace of mind that the print-run will deliver a successfully made, well-built part, meeting your expectations every time.

Meet the Pro L and XL

FELIX Pro L

Build size (LxWxH): 300 x 400 x 400 mm or 11.8” x 15.75” x 15.75”

Build volume: 48 Liter / 12.7 Gallon

FELIX Pro XL

Build size (LxWxH): 600 x 400 x 600 mm or 23.62″ x 15.75″ x 23.62″

Build volume: 144 Liter / 42 Gallon

Industrial applications with the FELIX Pro L and XL

Prototyping

- Design and test concepts with ease

- Very low to zero iteration cost

- Retain autonomy: produce and tweak multiple iteratinos until saved.Slash lead times with on-demand production and avoid outsourcing logistics

Tooling

- Create customizable tools fit for purpose.

- Tools such as jugs, fixtures, nozzles, feeder bowls and brackets.

- Create lighter, stronger and better tools.

- Improve ergonomic design.

Moulds

- Create casting moulds and masters

- Maintain control of the entire production process

- Maintain control of the entire production process

End-Use parts

- Agile production method facilitates quick production turnaround.

- Part cost is not connected with part complexity.

- low downtime in the production cycle.

Design, test and manufacture larger parts using robust and reliable 3D printing

3D Print Larger Parts

Save time

Cut down weeks of waiting on third party suppliers.

Quickly and easily modify designs for fast iterations.

Save Money

Features designed for your maximum benefits.

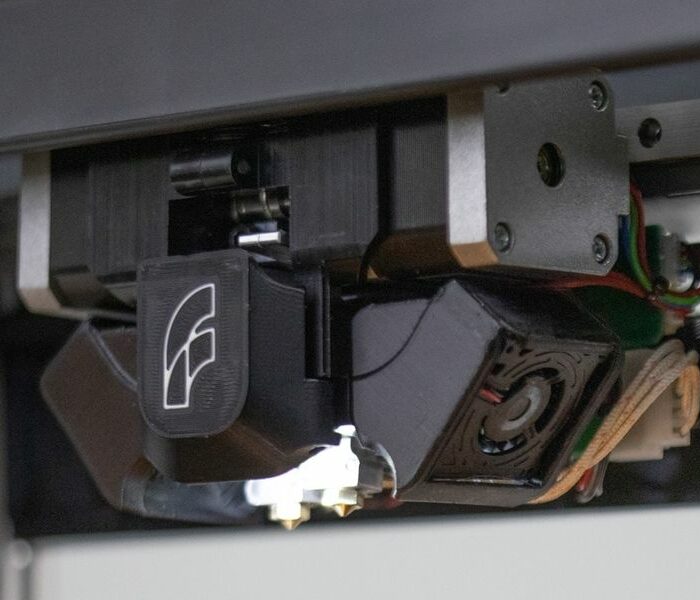

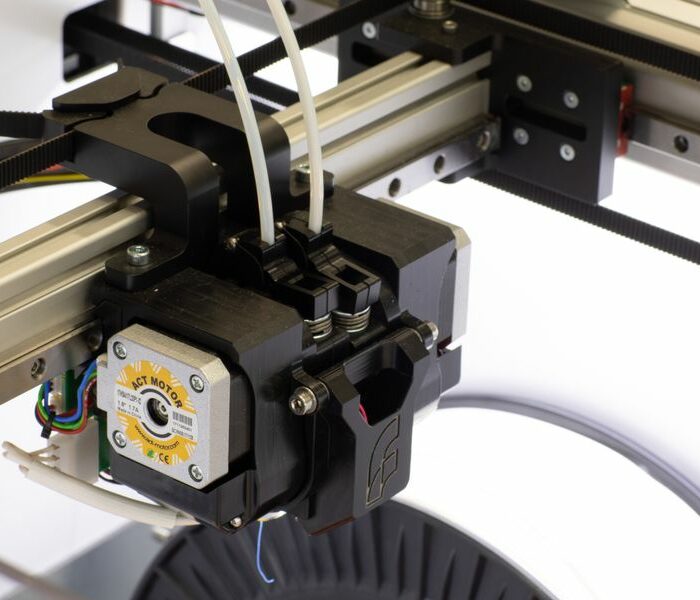

Dual Extrusion System

Enjoy maximum design freedom with dual head printing. Print more delicate objects with soluble support material. Allows printing with two types of materials or two colours in a single print job.

Print head nozzles intelligently move away when idle, to avoid collision. This ensures accurate printing at optimal speeds. Print heads are quick-swappable, this can be done without tools in a matter of seconds.

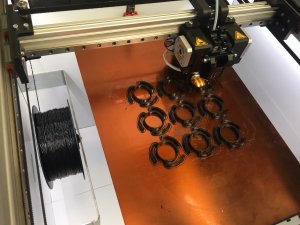

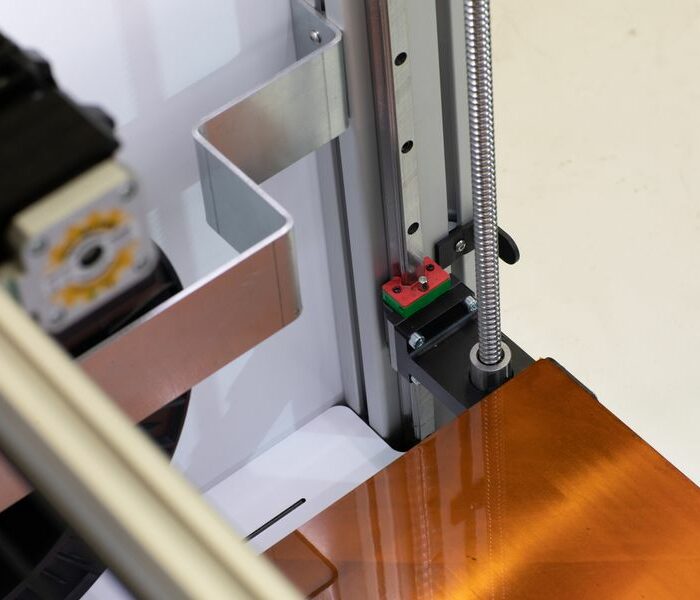

Heated Bed with convenient flex plate

The high power aluminum casted and milled print bed heats up evenly to the optimal temperature within a few minutes to ensure optimal print adhesion.

For easy object removal, simply bend the flexplate and the object simply pops off the plate.

Ease of use

Automatic calibration of the print-heads and printbed, ensure an accurately calibrated printer, resulting in optimal print results.

Powerfull best in class Simplify3D software is easy to start with, but also fully customizable for the power user.

Reliable

Enjoy 24/7 hassle free operation, due to the high quality components used in the printer.

For example, Linear HIWIN rails, rigid alumum frame, engineering grade plastics

All printers are under strict quality control, during the build process. Each printer is tested at least 48 hours before shipped out.

Print progress monitoring

To ensure your printjob is properly printed, the filament flow and the mains power are continuously monitored.

If filament is empty, the print will pause, till new filament is added.

If the mains power is lost, the built in UPS will save the print and allow the print to continue safely when the mains power is restored.

Never lose a print job or your valuable time.

Intuitive HMI

The touchscreen with embedded print server gives the FELIX Pro L/XL super powers.

Enabling remote print file monitoring, multi-user environment and print-filemanagment.

Last but not least it is so powerful that it can control upto 10 different printers to create a printfarm. Also an embedded webcam gives ultimate control of the print-process.

Wide Selection of materials

PLA

Premium PLA

PET-G

ABS-X

ASA-X

FLEX

Support Material

Implementing 3D printing as an effective prototype solution

The bottom line is I am past all of the novice mistakes and am now printing nice pieces with my FELIXprinter and I am extremely satisfied. I have been telling everyone about them and their dedication to service. An art that has been long lost with 90% of all other companies out there. Felix, Andy and the Pali Proto team all know and understand how to take care of a customer. I am very grateful for every one of them and I am looking forward to a fun 3D printing season.

Brad Martin, President A.F.C.

TECHNICAL SPECIFICATIONS

| Pro L | Pro XL | |

|---|---|---|

| Build Size XYZ (mm) | 300x400x400 | 600x400x600 |

| Build Volume (l) | 48 | 144 |

| Compatible materials | PLA, ABS, ASA, PVA, PETG, TPU, NYLON, and many more | |

| Layer height (mm) | 0.05 – 0.5 | |

| XYZ resolution (microns); | XY, 1.6, Z: 0.15 | |

| Print speed (mm/s) | 150 (max) | |

| Movement speed (mm/s) | 350 (max) | |

| Extruder type | Dual Direct Drive | |

| Filament Diameter (mm) | 1.75 | |

| Nozzle type | Standard 0.5mm brass, optional: 0.25, 0.35, 0.5 and 0.7mm hardened steel | |

| Nozzle temperature (˚C) | 280 | |

| Build platform | Aluminum casted buildplate, with spring steel flexplate | |

| Bed Temperature (˚C) | 110 | |

| Monitoring | Filament flow detection, Webcam, powerloss detection | |

| Bed Temperature (˚C) | 110 | |

| Machine Dimensions (mm); | 600 x 660 x 766 | 906 x 666 x 966 |

| Weight (kg); | 63 | 80 |

| Power Input | 110V (50Hz) – 220V (60Hz) | |

| Max Power (W) | 1600 | |

| Connectivity | USB, LAN, WIFI | |

| Safety Certification | CE | |

Download more information / Get quote?

Contact us, we are happy to discuss your application and needs to achieve a succesfull 3D printing experience.