Built for BIG performance. When you demand more from 3D printing.

When you demand more from 3D printing.

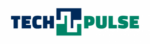

The new FELIX Pro L and Pro XL additive manufacturing systems have been designed to perform at scale, and both have been constructed to ensure reliable output for much larger parts.

These are manufacturing tools for every stage of the product development and manufacturing workflow with an optimal price and performance ratio that can meet the demands of industry.

• Large volume builds up to 144 liters

• Intelligent no-power detection for avoiding print failure

• Industrial quality 3D prints for prototyping and design

• Faster operations and ease of use with 7” touch screen

Pro L

-

Build size (LxWxH): 300 x 400 x 400 mm or 11.8” x 15.75” x 15.75”

-

Build volume: 48 Liter / 12.7 Gallon

Pro XL

-

Build size (LxWxH): 600 x 400 x 600 mm or 23.62″ x 15.75″ x 23.62″

-

Build volume: 144 Liter / 42 Gallon

“Lorem ipsum dolor sit amet, consectetur adipiscing elit, quis nostrud exercitation ullamco laboris nisi ut aliquip.”

– Stacy, CEO Print Shop

“It is the print quality that completely conquered my heart.

The result is a real gem.”

– Techpulse on FELIXprinters quality.

“Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ullamco laboris nisi ut aliquip.”

– Stacy, CEO Print Shop

Industrial Applications with the FELIX Pro L and Pro XL

Prototyping

- Produce full-scale, functional parts from the alpha phase to zero series

- Learn faster and iterate designs in hours and days, not weeks and months

- Avoid expensive, outsourced, and traditional slow production

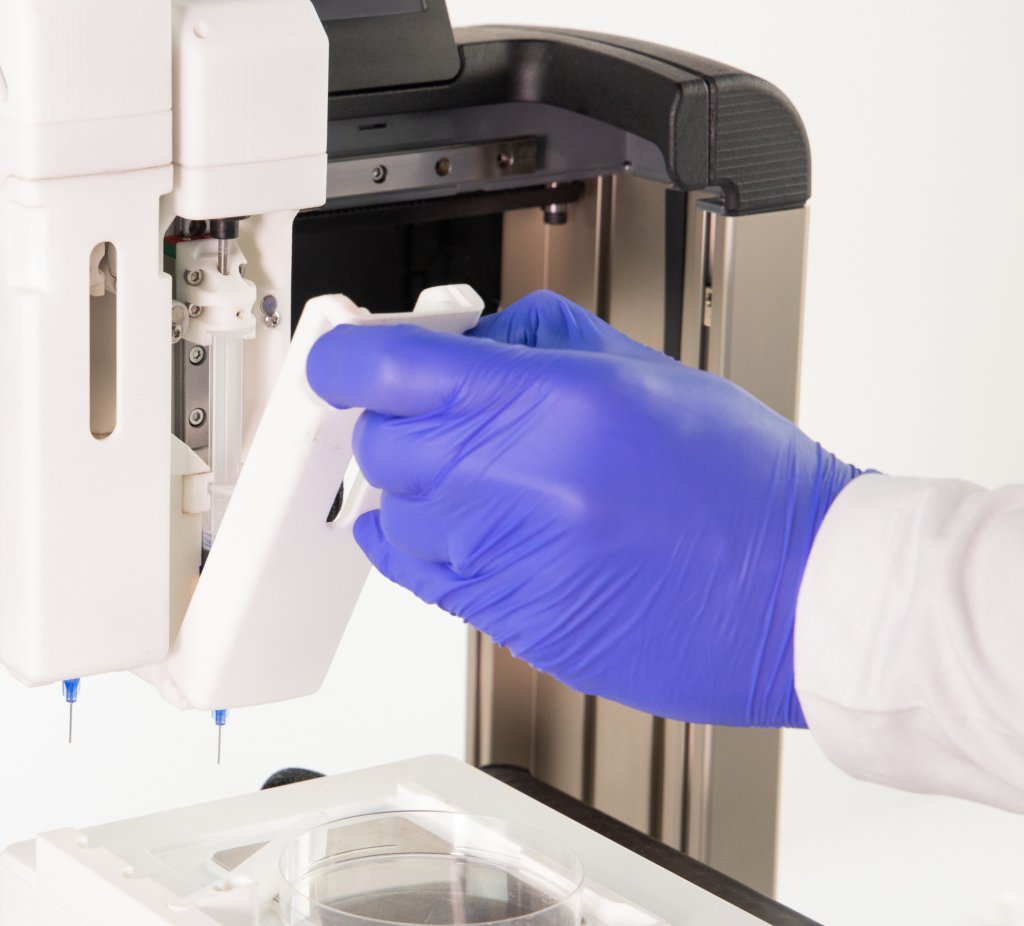

Tooling

- Customize tools for perfect fit, reduced weight, and ergonomic design

- Slash lead times with on-demand production and avoid outsourcing logistics

- Reduce production and material costs of optimized tooling

Moulds

- Replace high-cost patterns and molds made from expensive materials

- Speed up design iteration, product testing, and production

- Minimize outsourcing, external logistics, and supply chain dependence

End-use Parts

- From small-series production to unique parts without added costs

- Produce on-demand to reduce inventory and warehousing

- Reduce lead times and get to market fast to stay ahead of the competition

Whats Inside the new FELIX Pro L and Pro XL

Wide Slection of Filaments

The Pro L and XL can work with a wide selection of filament, including:

ABS

ABS

PLA

PLA

PETG

PETG

PVA

PVA

Temparature Controled Zones

The cool zone houses the printer’s electronics, making sure that they don’t overheat and cause problems.

Intelligent features that remove many of the tedious and time-consuming hurdles.

When the dual extruders are printing together they are at different print levels, avoiding any collisions and minimizing print failure.

The printers also integrate dual extrusion printing and a special mechanism that ensures the print heads operate symbiotically. That is, when the dual nozzles are printing they remain at different print levels, eliminating any risk of collision and reducing the chances of print failure. Further, if only one nozzle is in use, the other will automatically rotate away from the print, so that there is no interference.

Other features, such as an intuitive 18 cm touchscreen module with integrated print-server, are similar to those in the Pro 3 3D printer model. This particular feature, consisting of a “small but powerful” octacore computer, enables users to remotely monitor their prints via webcam, manage print files, render G-codes and even create a time lapse of the print. In terms of connectivity, the large-format 3D printers can be accessed by USB and/or WiFi, and can be connected in a LAN network or as a standalone machine.

Both the Pro L and Pro XL have been designed specifically to be easily portable — at installation or within a manufacturing setting. Both can be easily transported through a normal office door opening (900 mm).

Years of experience

in precision engineering.

Benefit from the advantages of additive manufacturing, without the hassle. The Pro L & XL offer unmatched ease of use for professional large volume 3D printing.

The design of the FELIX Pro L & XL allows for the installation of future hardware upgrades with no fuss. Which means that you benefit from any new future developments. The ‘write off’ time of the 3D printer is therefore impressively low and makes it a very cost-effective investment. The release cycles for upgrades are approximately one per year. FELIX strives to achieve the best possible performance in the most cost-effective way.

Full 3 year warranty for non-wearable parts, upgradeable to 5 years through periodic servicing. Flex plate for easy and damage-free object removal. Interchangeable flex print platform and print heads.

Pro L

-

Physical dimensions (LxWxH): 600 x 666 x 776 mm or 24” x 26” x 31”

-

Total weight: approx. 63 kg

Pro XL

-

Physical dimensions (LxWxH): 906 x 666 x 966 mm or 37” x 26” x 38”

-

Total weight: approx. 80 kg

Instructions and features for the Pro L & XL

Download More Information / Get a Quote?

Additional downloads: