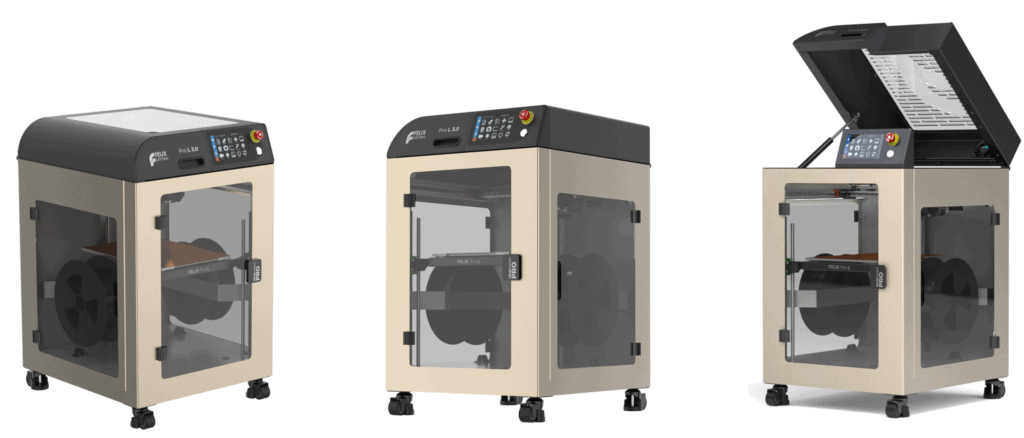

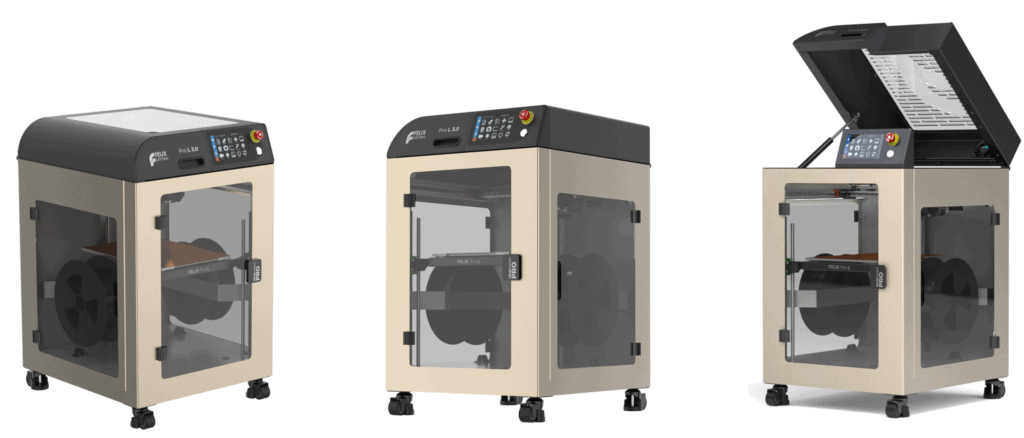

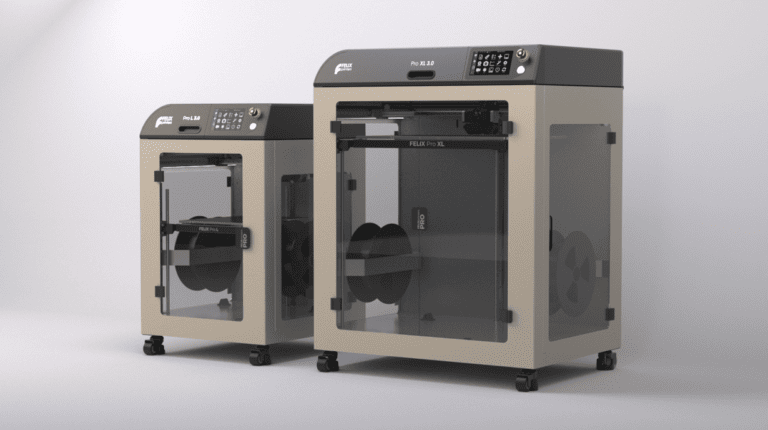

NEW: FELIX Pro L / XL 3.0

Large scale FDM 3D printing, fast, reliable, versatile and exceptional quality.

Dual

Direct drive

L: 300 x 400 x 400 mm

XL: 400 x 600 x 600 mm

Build Volume

Up to 150 mm/s

Print Speed

PLA, ABS, NYLON, TPU

Materials

Why FELIX Pro L/XL 3.0?

Enjoy the best 3D printing experience. Fulfill your projects in time, create the best usable prototype from very small to very large.

Curious? Please read ahead and discover how the Pro L or XL can be your best investment to date.

Industrial applications with the FELIX Pro L and XL

Prototyping

- Design and test concepts with ease

- Very low to zero iteration cost

- Retain autonomy: produce and tweak multiple iteratinos until saved.Slash lead times with on-demand production and avoid outsourcing logistics

Tooling

- Create customizable tools fit for purpose.

- Tools such as jugs, fixtures, nozzles, feeder bowls and brackets.

- Create lighter, stronger and better tools.

- Improve ergonomic design.

Moulds

- Create casting moulds and masters

- Maintain control of the entire production process

- Maintain control of the entire production process

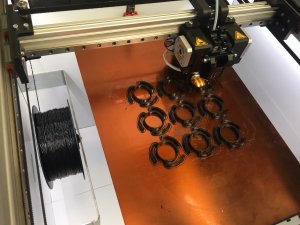

End-Use parts

- Agile production method facilitates quick production turnaround.

- Part cost is not connected with part complexity.

- low downtime in the production cycle.

Design, test and manufacture larger parts using robust and reliable 3D printing

3D Print Larger Parts

Save time

Cut down weeks of waiting on third party suppliers.

Quickly and easily modify designs for fast iterations.

Save Money

Ease of Use

Make your 3D printing dreams come to life with ease. With our easy-to-setup printers, you’ll be up and running in no time, leaving you more time to focus on creating the amazing models and prototypes you’ve been dreaming of.

Auto calibration

Swappable flexible build plate.

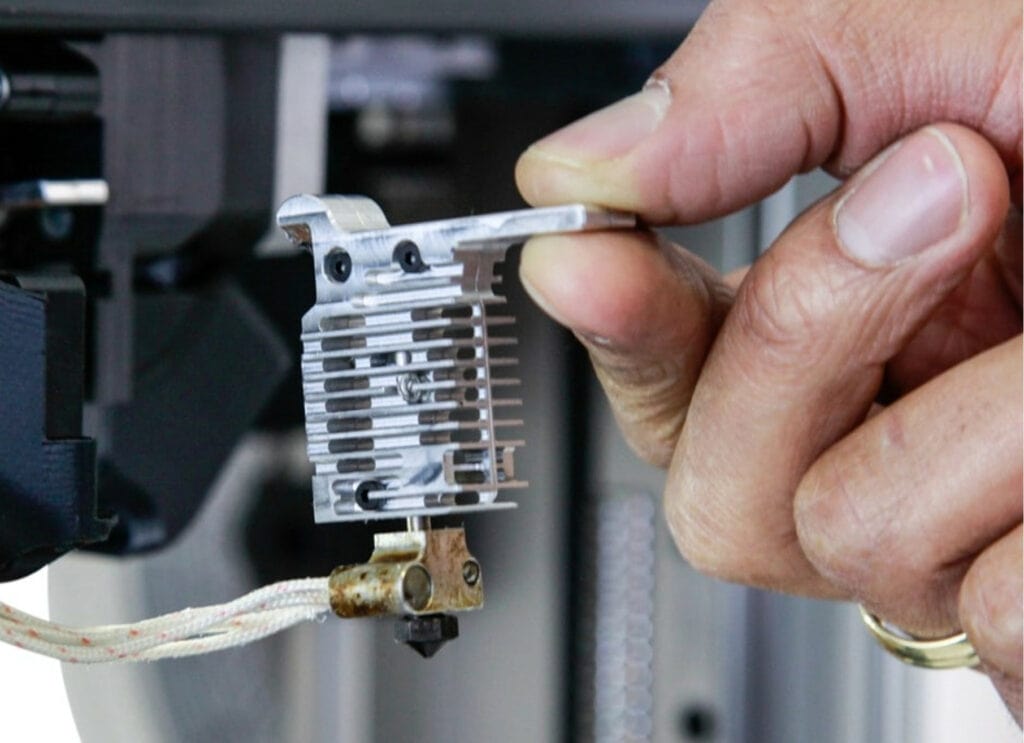

Quickswap hot-end

Low operating noise, < 45dB

32-bit motion controller enables silent and smooth movements of the components. Use the printer in an office environment without disturbance.

7-inch touch display

We’re committed to providing you with an effortless 3D printing experience. So, why wait? Choose our printers and start creating amazing prints with ease. Order now and experience the difference for yourself.

Reliability

Less is more

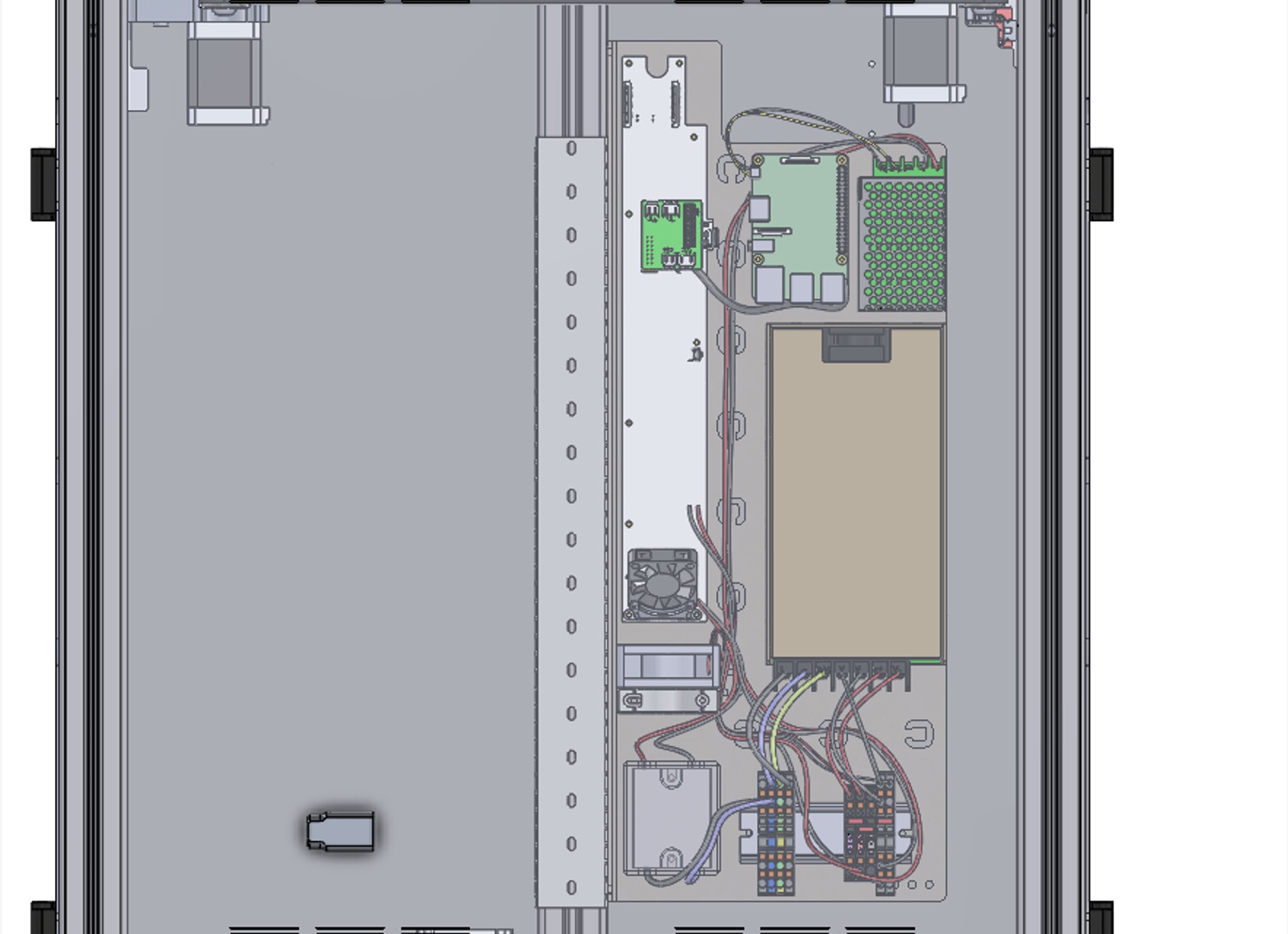

The design philosophy of the FELIX Pro L 3.0 is based on the principle, less is more. We strive to have the minimum number of bolts and find structural strength in the smart shapes and or combining parts in an efficient way.

A big benefit from this is that the less parts there are, the less things that can go wrong and also robustness and quality improves. Less things to maintain etc.

Made from top-notch materials

Industrial motion

CNC milled

3D printing

Operational Reliability

- Higher uptime,

- Lower maintenance and operational costs.

- Last but not least a lasting great experience with your 3D printing companion.

Filament flow monitoring

Out of filament detection and also filament flow measurement. Ensures no print is ruined due to filament issues.

This simple yet effective feature pauses your printer when the spool is empty or entangled, enabling maximum success.

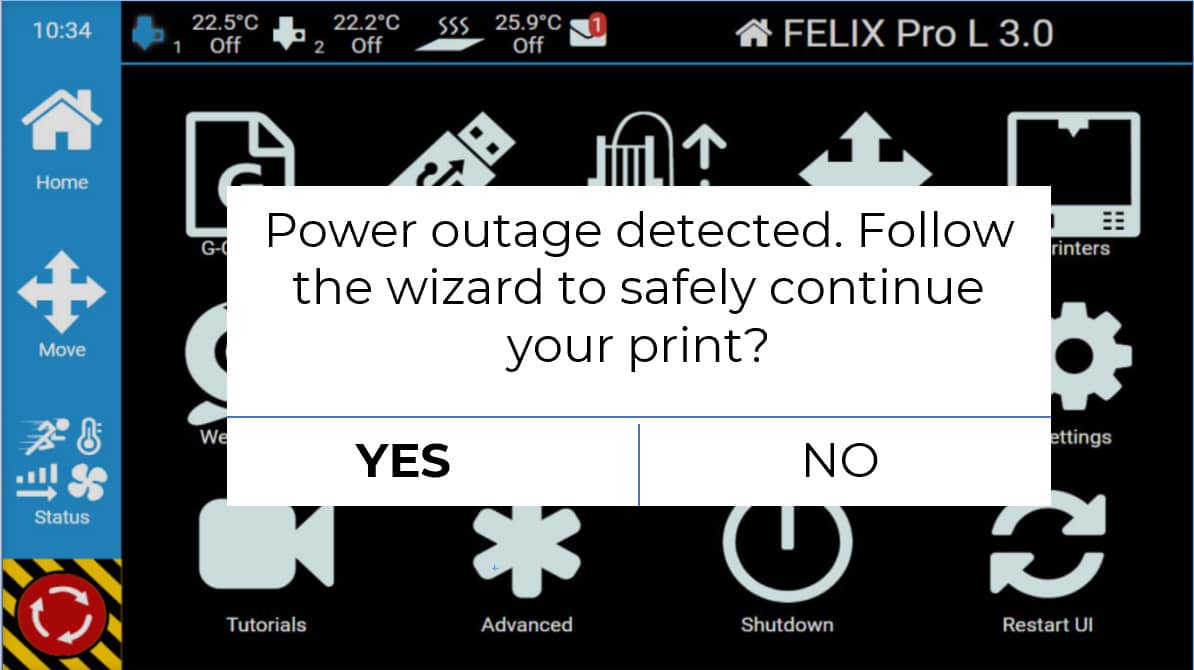

Power loss recovery

Avoid the frustration of a ruined 3D printing project due to a power outage with the power outage recovery feature.

Keep your project on schedule and prevent wasted time and filament.

Performance

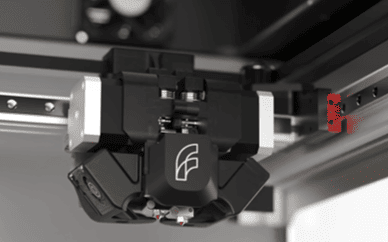

Dual

Direct drive

L: 300 x 400 x 400 mm

XL: 400 x 600 x 600 mm

Build Volume

Up to 150 mm/s

Print Speed

15 mm3/s

Extrusion speed

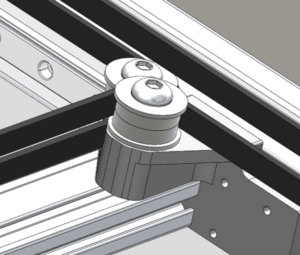

Motion system

The new and improved coreXY motion system is one of the most dynamic motion systems. Two motors work simultaneously to create a movement of the extruder.

Especially for quick changes in direction this is the goto motion system. For the end user this means crisp prints in less time.

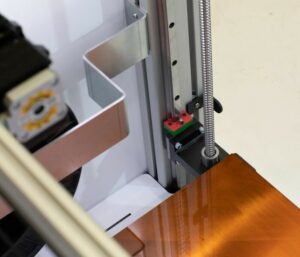

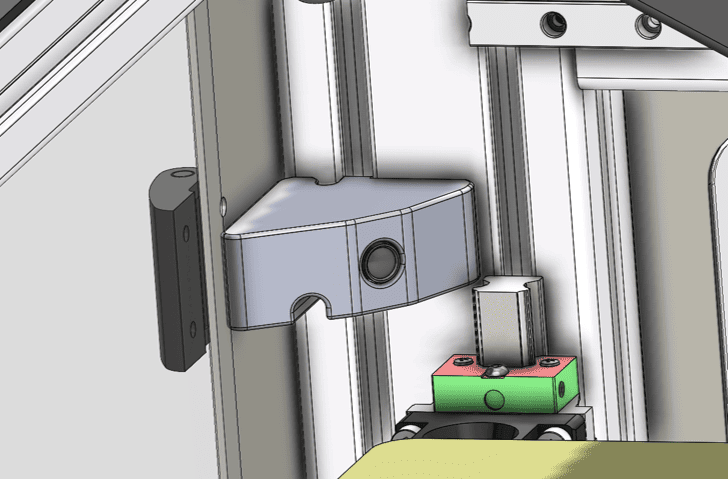

New Z-axis assembly

GT3 belts ensure accurate motion. The high precision leadscrews ensure smooth operation and accurate printresults. The motor is placed in the cold zone of the printer, ensuring longer lifetime and easier access for maintenance.

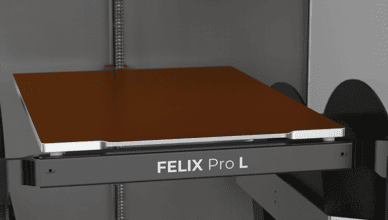

Flat Bed

A flat print surface is important for an optimal print result. The printbed of the Pro L and XL features:

- Plan cast aluminum. Meaning it has no internal stress ensuring the flatness of the plate through countless heatup cycles.

- Evenly heated by a rubber etched silicone heater.

- Short heatup times due to high power of 1kW

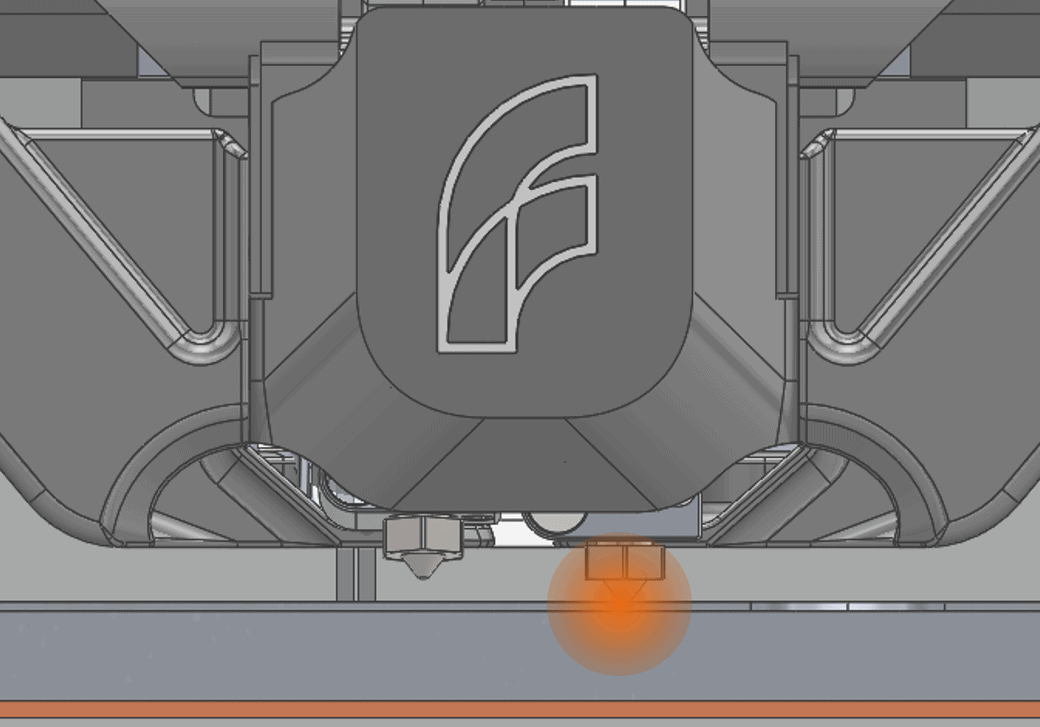

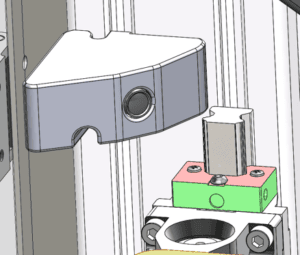

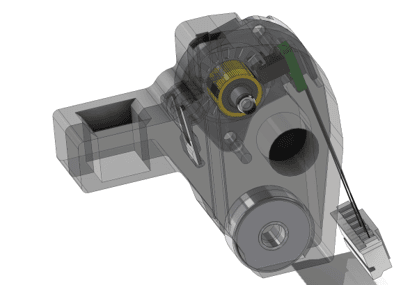

Dual Extruder

The dual head extruder ensures optimal design freedom. Multi material or multicolor prints are at your disposal

- Our extruders boast

Copper heater body, more stable heat - Smart Extruder switch system

- Integrated z-sensor, ensuring an optimal first layer every time.

- Optional bond tech nozzle enabling 2x more flow.

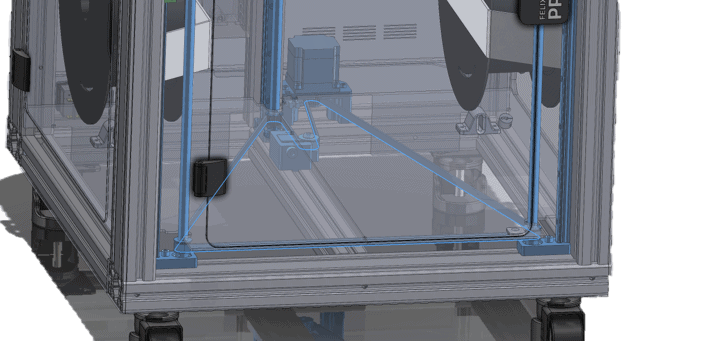

Design

A perfect blend of form and function. The easy-to-lift top cover and improved accessibility, enable ease of use. The new side doors provide better access to filament spools.

Designed for optimal efficiency

Upgradability

At FELIX, we believe in staying ahead of the curve. That’s why our printers are upgradeable and always future-proof. With our commitment to innovation, you can rest assured that your investment will last for years to come, saving you money on long-term operational costs.

Upgrade kits coming soon …

Webcam

With the webcam module, you are able to monitor your print-jobs to check the status of the printjob. In case the printer is connected to the network, you can also check the print progress from outside the office.

Very convenient for the over the weekend print-jobs and you want to know what is going on.

Software

Our printers are open to use any software, however to make it easy, we deliver the printers with the best and most versatile software available. Simplify3D.

The intuitive interface and preconfigured slice profiles makes the learning curve minimal.

Wide Selection of materials

PLA

Premium PLA

PET-G

ABS-X

ASA-X

FLEX

Support Material

TECHNICAL SPECIFICATIONS

| Pro L | Pro XL | |

|---|---|---|

| Build Size XYZ (mm) | 300x400x400 | 600x400x600 |

| Build Volume (l) | 48 | 144 |

| Compatible materials | PLA, ABS, ASA, PVA, PETG, TPU, NYLON, and many more | |

| Layer height (mm) | 0.05 – 0.5 | |

| XYZ resolution (microns); | XY, 1.6, Z: 0.15 | |

| Print speed (mm/s) | 150 (max) | |

| Movement speed (mm/s) | 350 (max) | |

| Extruder type | Dual Direct Drive | |

| Filament Diameter (mm) | 1.75 | |

| Nozzle type | Standard 0.5mm brass, optional: 0.25, 0.35, 0.5 and 0.7mm hardened steel | |

| Nozzle temperature (˚C) | 280 | |

| Build platform | 8mm aluminum casted buildplate, with spring steel flexplate | |

| Bed Temperature (˚C) | 110 | |

| Monitoring | Filament flow detection, Webcam, powerloss detection | |

| Machine Dimensions (mm); | 600 x 660 x 766 | 906 x 666 x 966 |

| Weight (kg); | 63 | 80 |

| Power Input | 110V (50Hz) – 220V (60Hz) | |

| Max Power (W) | 1600 | |

| Connectivity | USB, LAN, WIFI | |

| Safety Certification | CE | |

Download more information / Get quote?

Contact us, we are happy to discuss your application and needs to achieve a succesfull 3D printing experience.