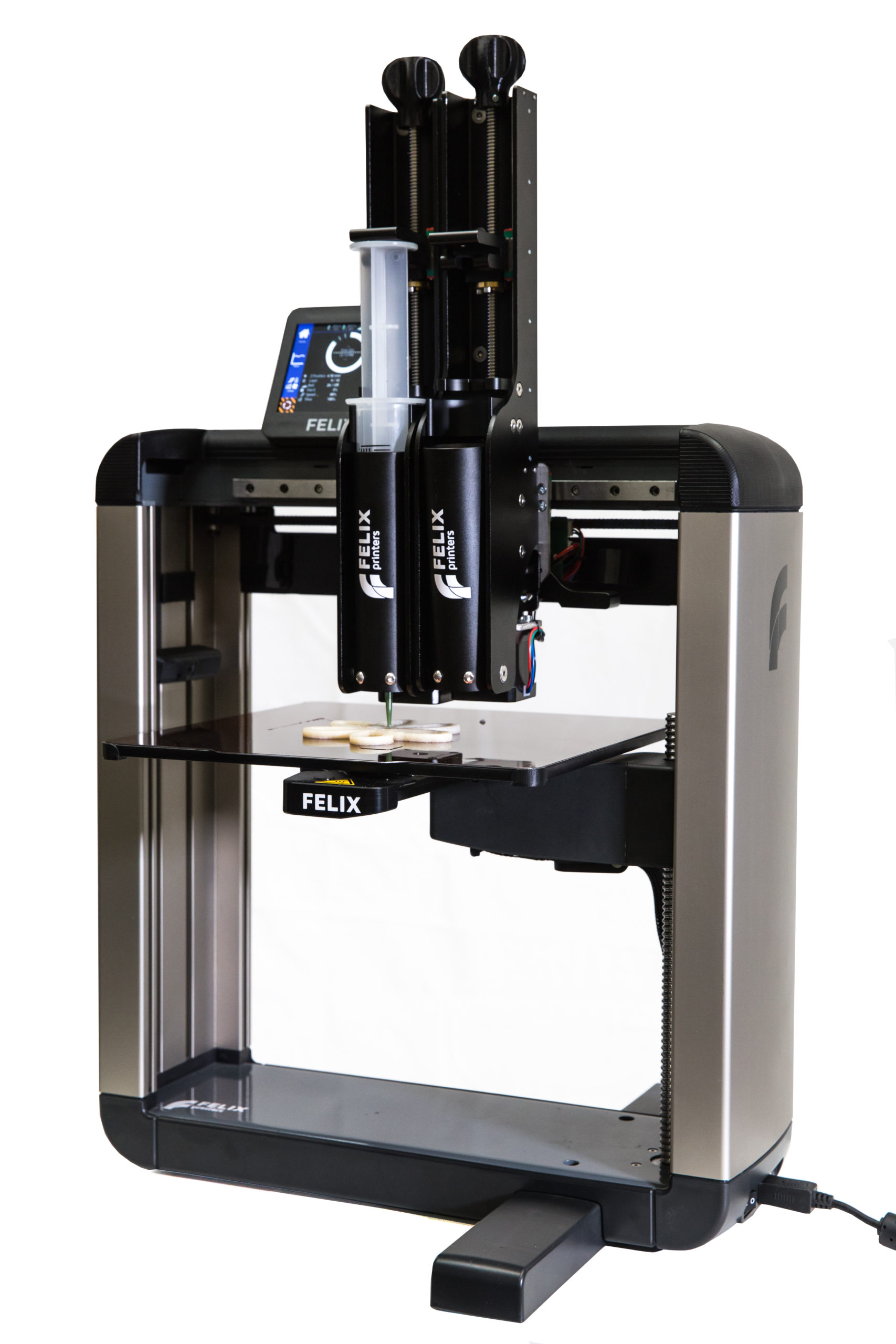

The New

FELIX

FOOD

3D Printer

Create 3D printed culinary masterpieces

3D print pastes, chocolate, vegetable purée, meat, soya and more.

FELIX 3D FOOD printer features

The FELIX 3D FOOD printer is a revolutionary step toward reinventing the line-up of tools used in the kitchen. Chefs will enjoy using the intuitive and reliable machine to get the inventive results they desire.

User-friendly

Intuitive touch-screen guides users through printing process

Sturdy, durable design

Reliability of the machine and parts are guaranteed. Highest grade materials are used, to ensure quality

Dual syringe system

Dual syringe with a capacity of 2x 100ml

Luer lock nozzle

Standardized syringes, with luer lock nozzles. 0.15mm upto 2.5mm)

Heated print bed

The print-bed can be heated upto 105 degC.

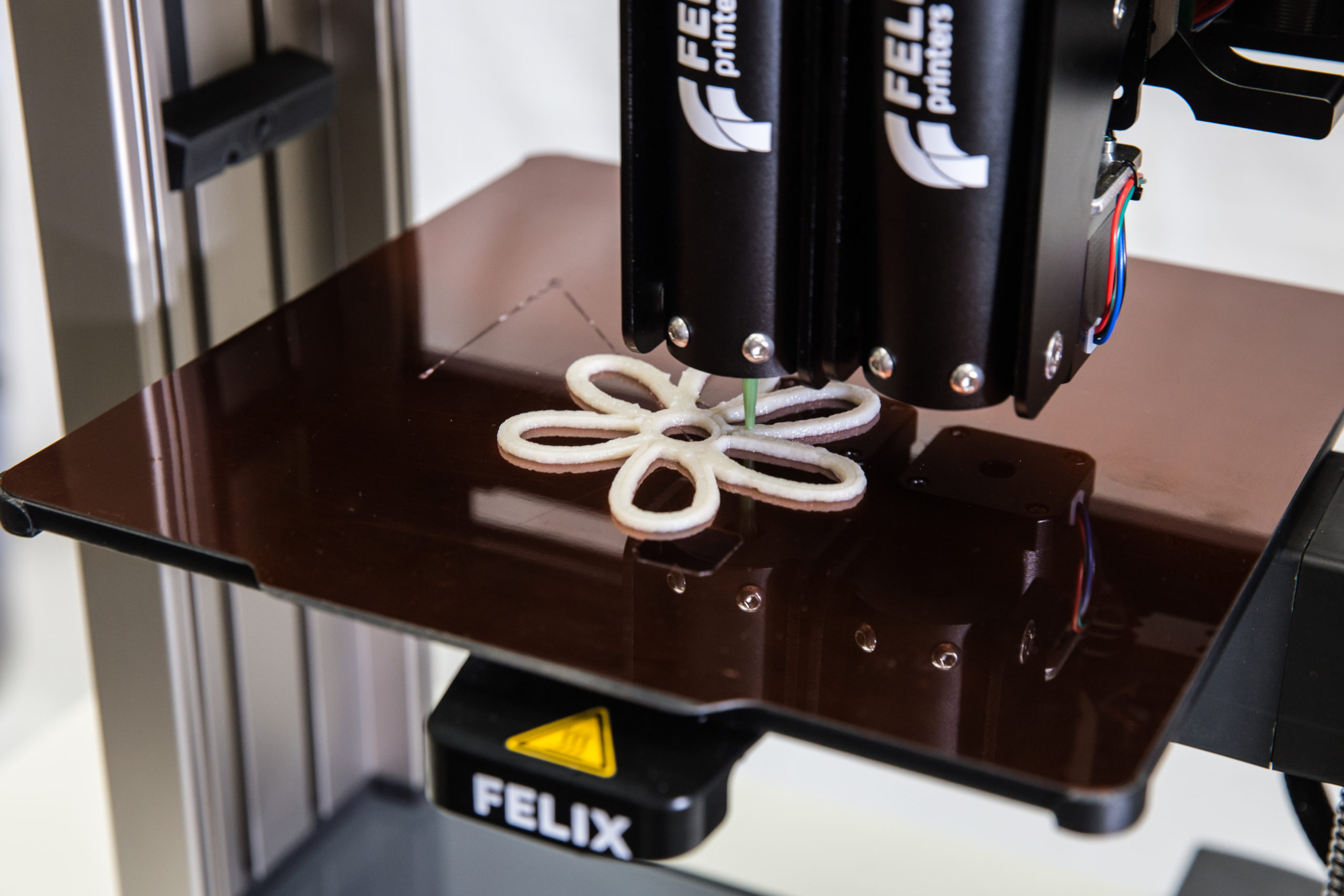

Functionality

A broccoli frog…

Easter bunny butter…

Or even look-alike salmon

The FELIX FOOD 3D printer makes your cuisine dreams come true.

Automatic bed levelling

The first layer is the foundation of a successful print. The automatic bed levelling system probes various points to calculate the level, eliminating human error.

Extrusion system

Even, consistent and accurate material flow are key for a smooth, stunning print result. The retraction dispensing system gives you ultimate control and repeatable results.

Small and large batch quantities

Small- or large-scale catering can be facilitated with the FELIX FOOD, multiple printers can be used in series, or for singular production.

Applications

It’s time to reimagine your plate. Rethink ingredients. See food in 3D

What can be 3D printed?

- Vegetable pastes

- Fats

- Chocolate

- All paste-like edible substances

Why 3D print food?

- Beauty and aesthetics

- Reach new markets – transform a child’s experience of vegetables and food

- Create new interesting experiences for those with trouble chewing and swallowing

- Break the mould with objects beyond the traditional

Technical Specifications

Create 3D printed culinary masterpieces

System specifications

- Printer dimensions (L, W, H) 430 x 390 x 550 mm

- Weight 13 kg

- Power requirements: 220 V

- Power usage: Max 150W

Capabilities

- Build volume (L, W, H) 155 x 195 x 170mm

- Layer height range 0.1 – 3 mm

- Bed temperature: max. 105°C

- Motorized bed leveling

- Fully automatic xyz nozzle calibration

- Optional: Heatable syringes (upto 90 °C)

Extruders

- Dual extruder

- Innovative probe mechanism

- Automatic xyz nozzle calibration

- Standardized 100cc luer lock syringe compatible

HMI interface

- Touchscreen

- Print file management

- 16GB memory

Print materials

- Any paste like substance.

- Viscosity: 50 Pa*s upto 1000 Pa*s

Connectivity

- WIFI

- Wired Ethernet

Software

- Simplify3D