WE ARE CELEBRATING....

10 Years

of

Timeline of company development

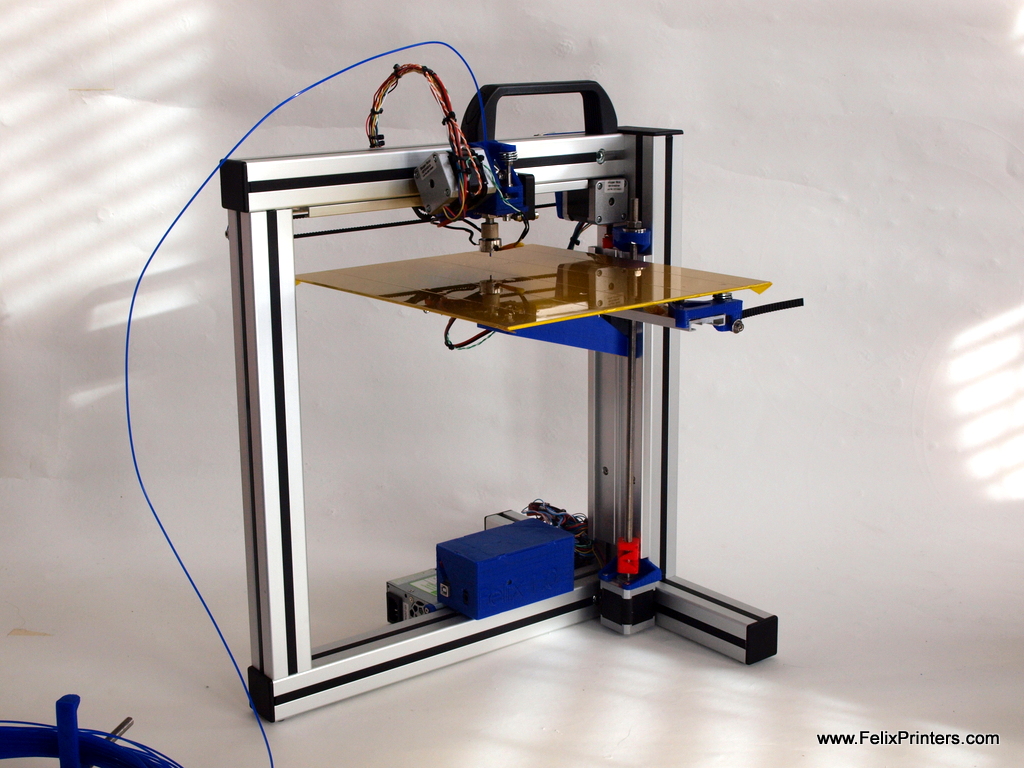

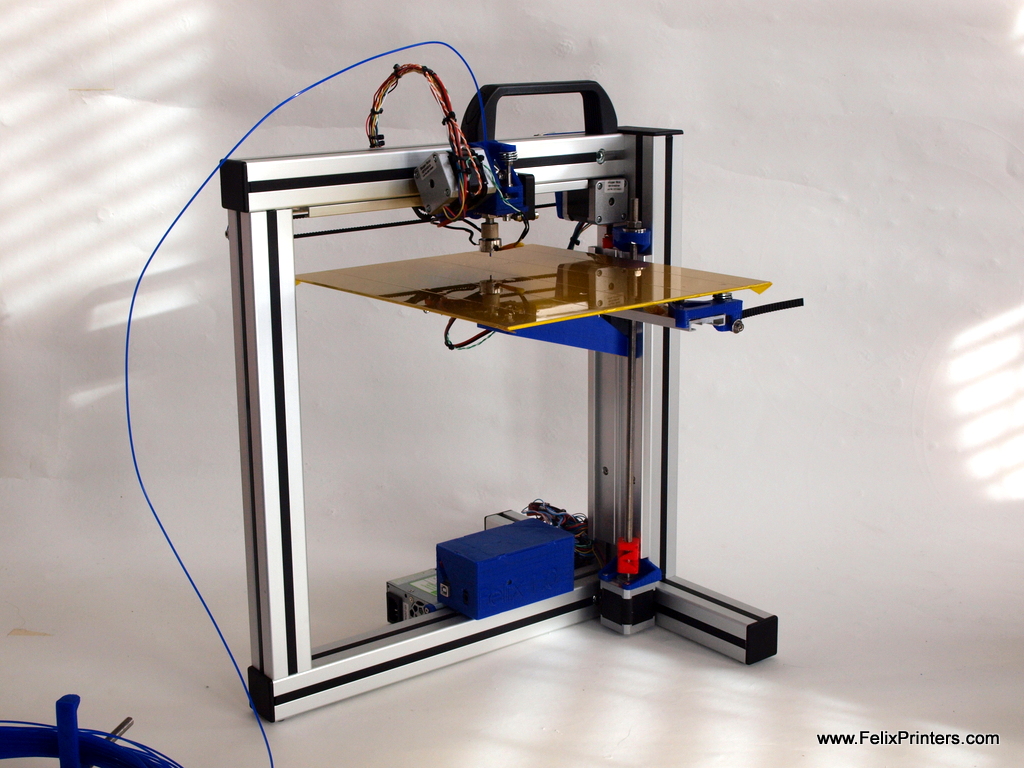

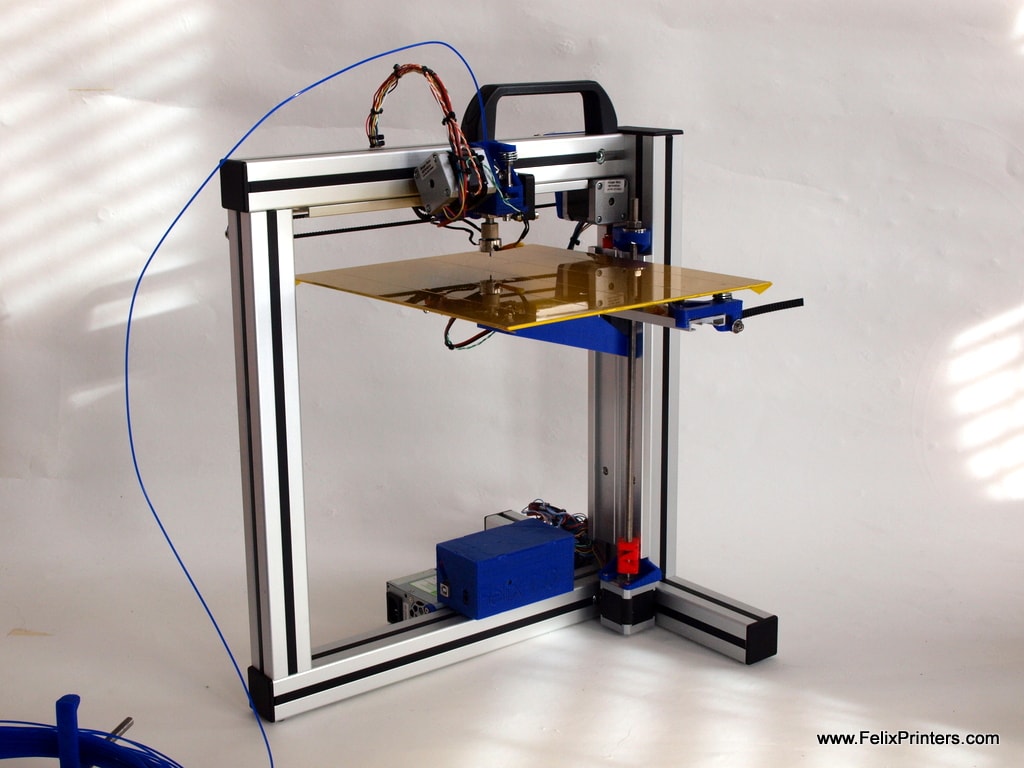

FELIXprinters started with a completely different mission in mind. Founder Guillaume Feliksdal had the idea to build a humanoid walking robot. He decided to use 3D printing to produce the parts that he needed. At that stage in 2011, 3D printing was still in its infancy stage. He used a DIY 3D printer, but found that there was much room for improvement. This inspired him to build his own 3D printer.

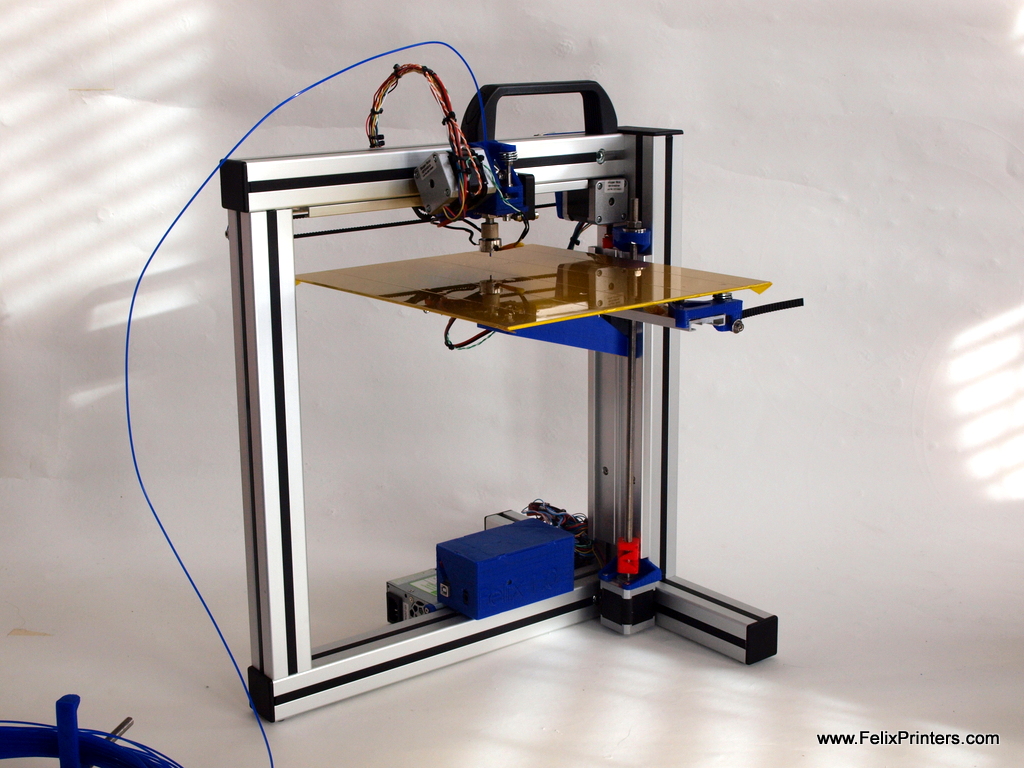

In his attic room in the evening hours after work, he created the first version. He named the printer with a play on words with his surname and the FELIX 1 was born.

FELIXprinters started with a completely different mission in mind. Founder Guillaume Feliksdal had the idea to build a humanoid walking robot. He decided to use 3D printing to produce the parts that he needed. At that stage in 2011, 3D printing was still in its infancy stage. He used a DIY 3D printer, but found that there was much room for improvement. This inspired him to build his own 3D printer. In his attic room in the evening hours after work, he created the first version. He named the printer with a play on words with his surname and the FELIX 1 was born.

Guillaume Feliksdal, founder and co-owner of FELIXprinters. His background as engineer, industrial automation expert, automotive and robotics has served him well in the development and growth of the company in the last 10 years.

After the first sale, Guillaume and his father, Wilgo Feliksdal decided to focus entirely on growing FELIXprinters as a company. Wilgo leveraged his decades of experience as Application Engineer and Project Manager to guide the company’s commercial growth.

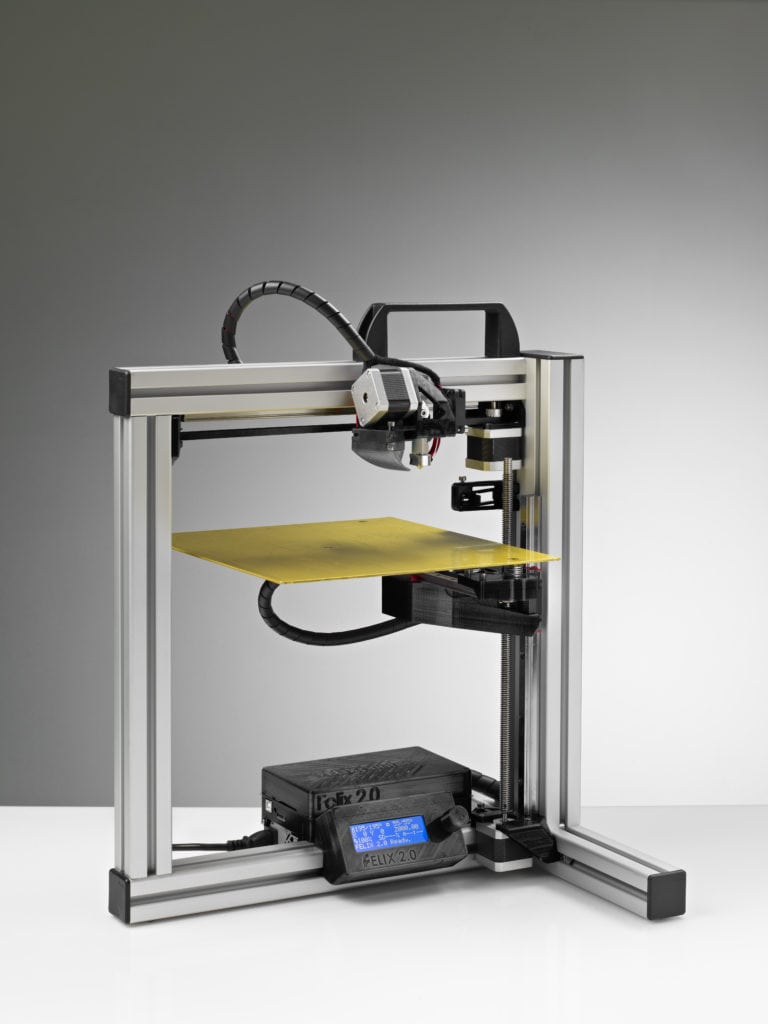

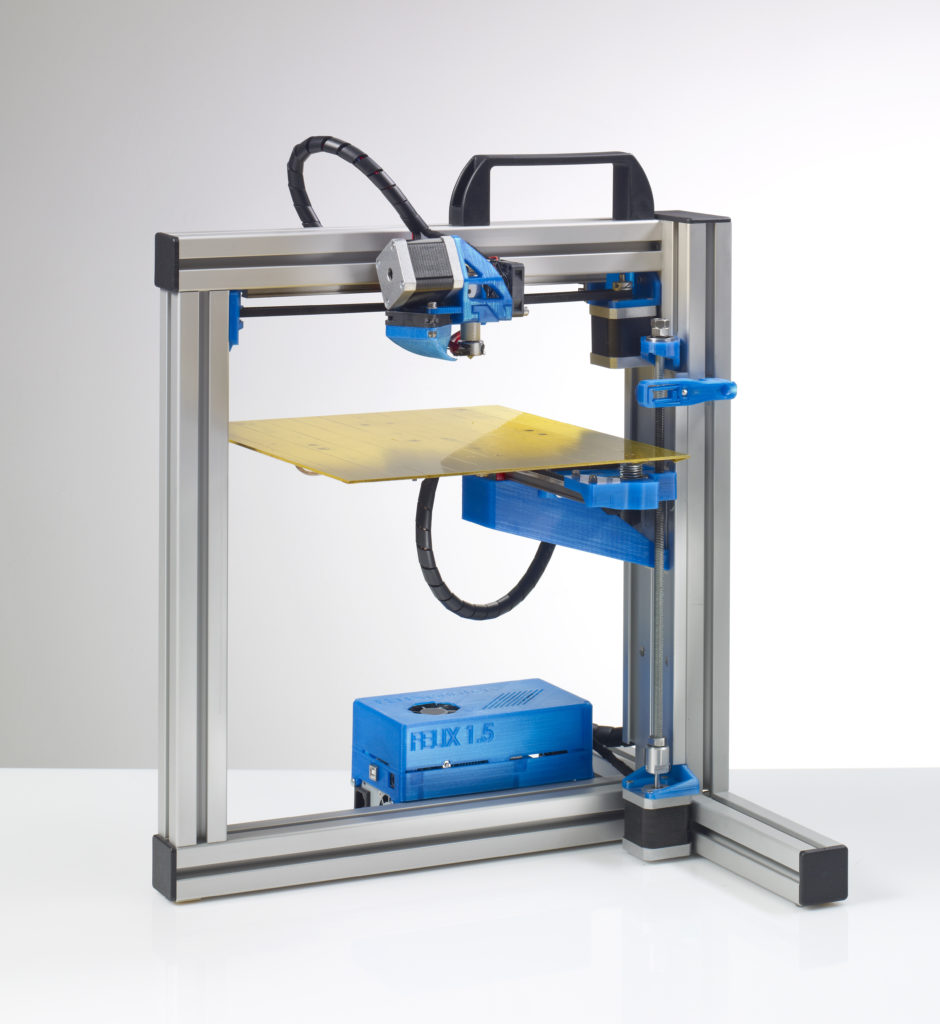

Further product development resulted in the FELIX 1.5 being launched in October 2012.

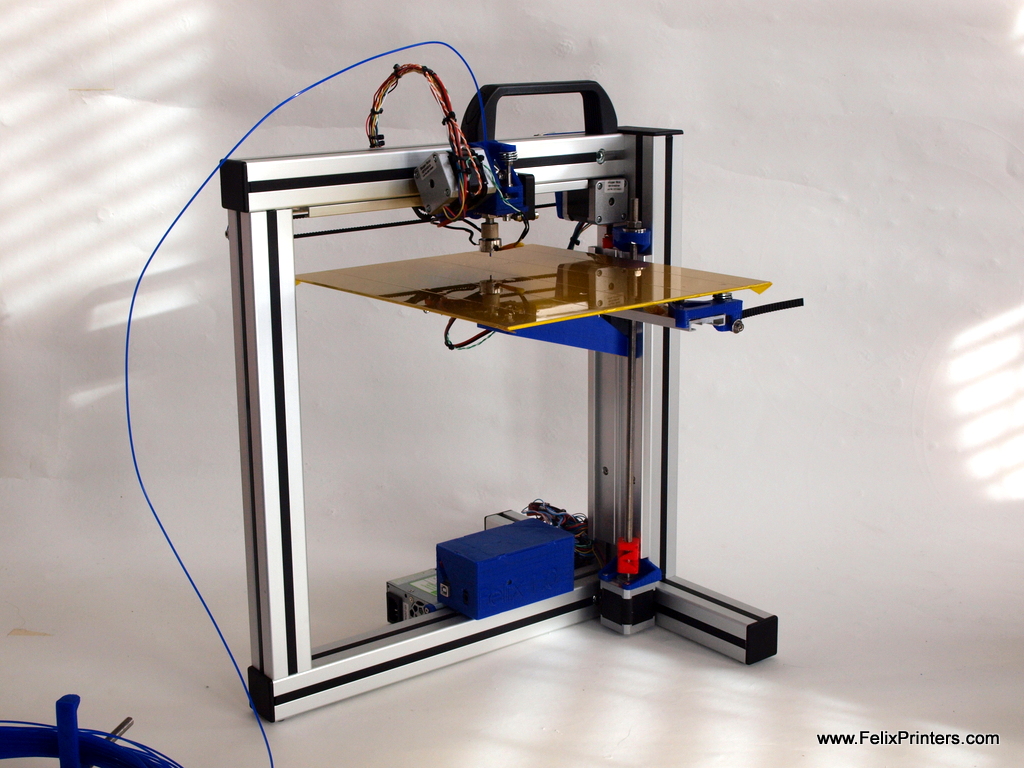

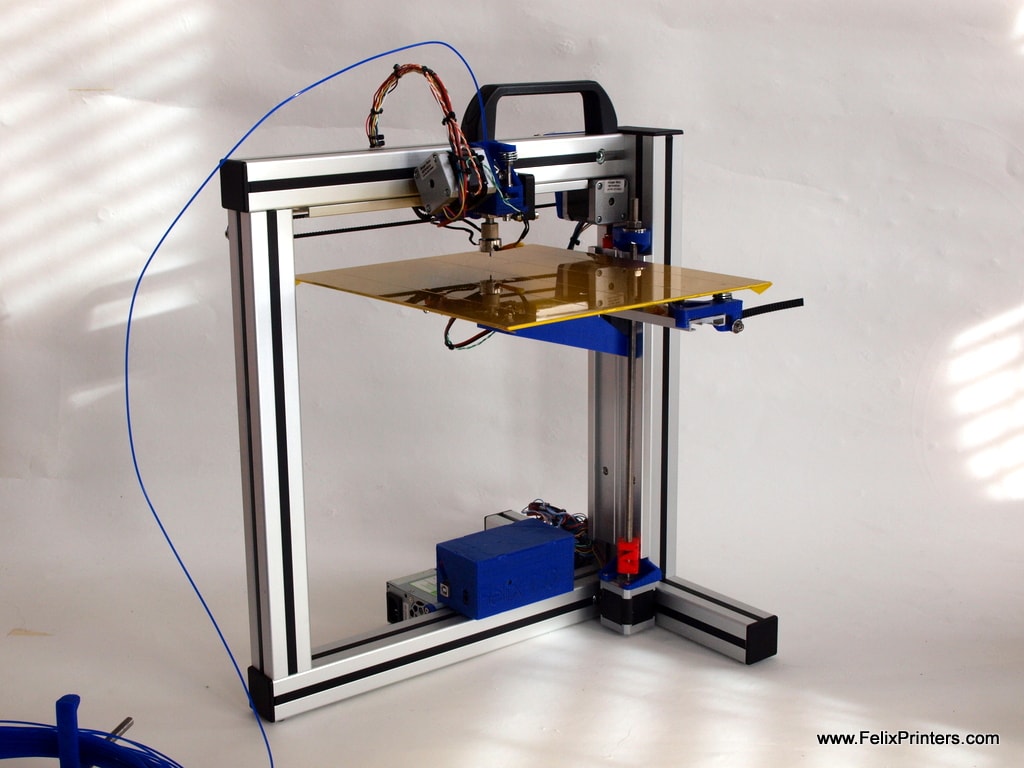

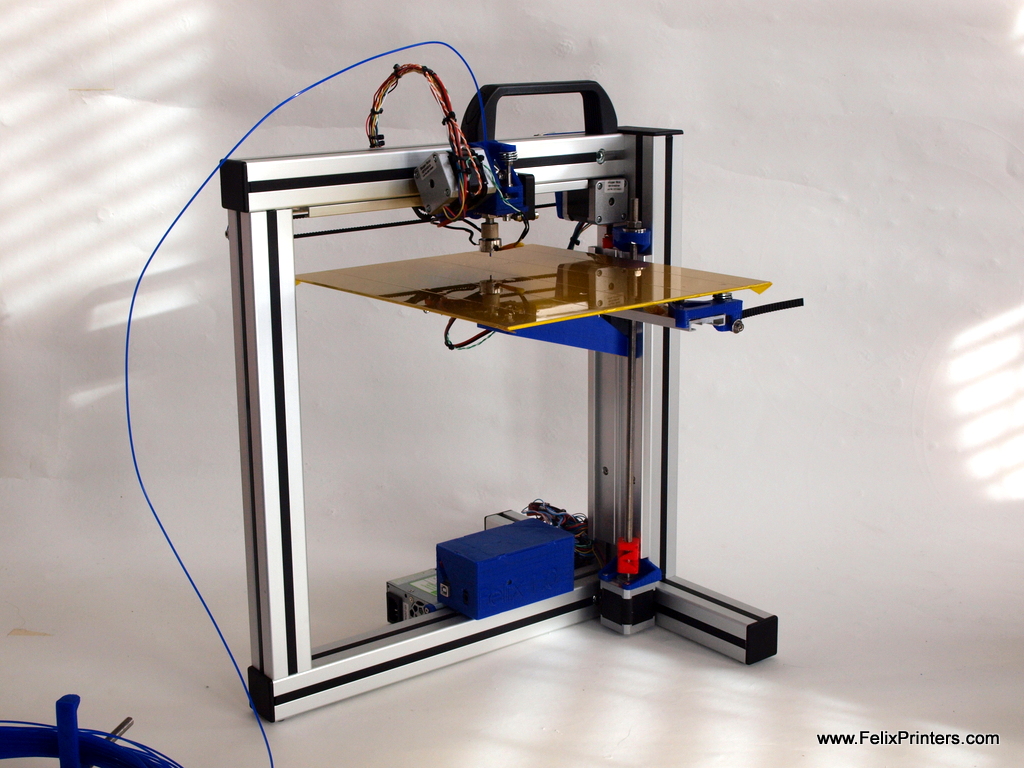

FELIX 1.0

Guillaume Feliksdal, founder and co-owner of FELIXprinters. His background as engineer, industrial automation expert, automotive and robotics has served him well in the development and growth of the company in the last 10 years.

At this stage of the company’s development, FELIXprinters served the personal and hobbyist market with DIY kits. The signature open aluminium frame became the blueprint from which further developments were built on.

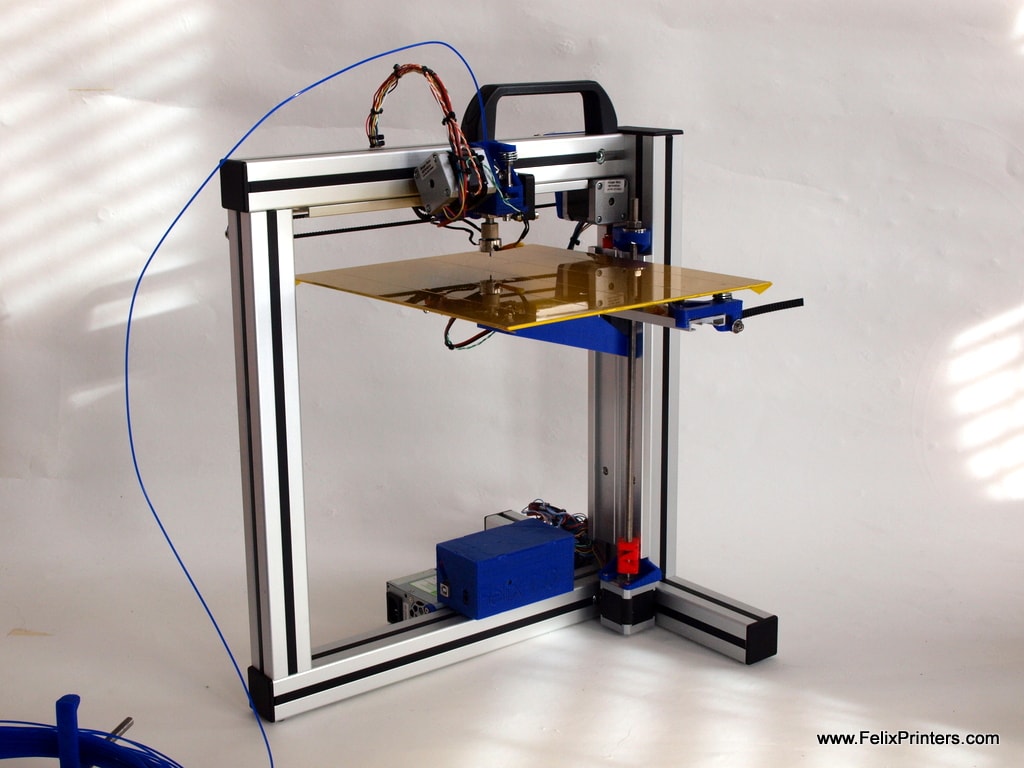

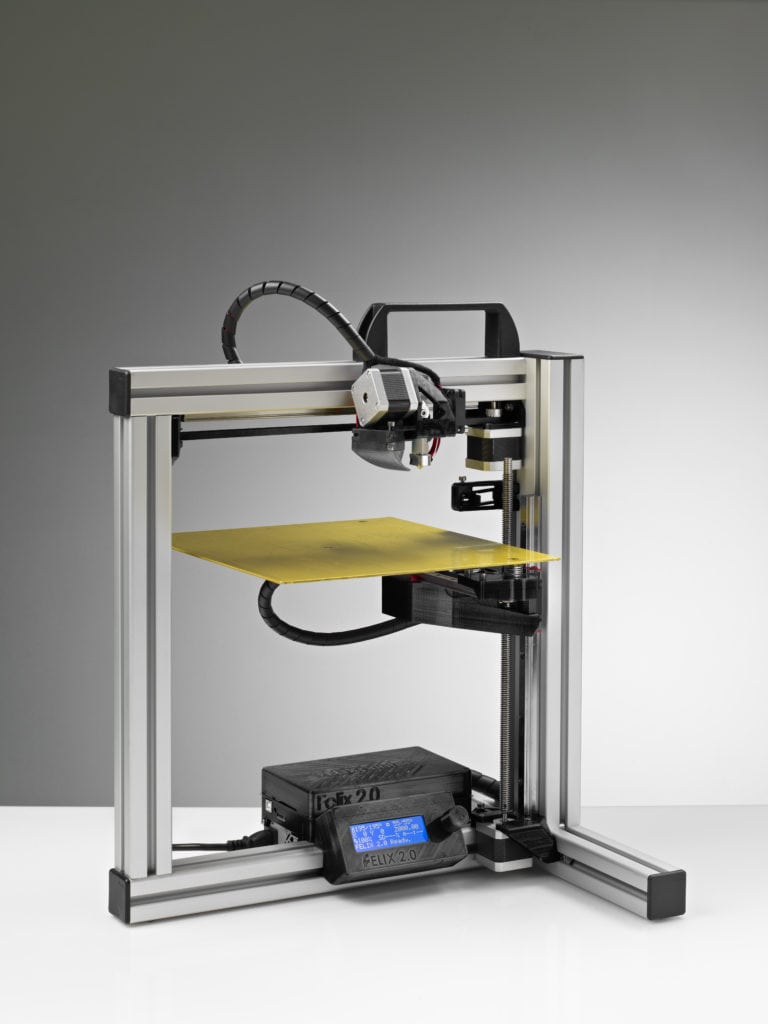

The FELIX 2.0 was born in May 2013. This FELIX increased its intelligent precision mechanisms, setting the tone of the quality FELIXprinters will become known for.

FELIX 2.0

The dual print-head FELIX 3.0 was launched. This advancement in technology allowed users to use two colour filment or two types of filaments simultaneously in a single print. Users loved the fact that they could use any filament available on the market at this stage, to print.

FELIX 1.5

Wilgo Feliksdal combines his mechanical expertise with management skills and together with his son Guillaume, forms the solid base on which FELIXprinters can answer to the growing industry demands, with 3D printing solutions

From hobbyist to professional

FELIXprinters made a strategic shift to start serving the professional 3D printing market with the introduction of the FELIX Pro 1. This next generation 3D printer was aimed at making 3D printing as convenient as possible, while delivering exceptional print quality.

We revealed its iconic design made with only the best durable components.

Common 3D printing problems were solved in this design. The auto calibration system allows users to establish the perfect first layer, without human intervention. Filament detection pauses a print if filament runs out, so you can reload and continue where you left off. Two interchangeable full metal print heads with intelligent sensors to avoid collision.

FELIXprinters started with a completely different mission in mind. Founder Guillaume Feliksdal had the idea to build a humanoid walking robot. He decided to use 3D printing to produce the parts that he needed. At that stage in 2011, 3D printing was still in its infancy stage. He used a DIY 3D printer, but found that there was much room for improvement. This inspired him to build his own 3D printer. In his attic room in the evening hours after work, he created the first version. He named the printer with a play on words with his surname and the FELIX 1 was born.

Guillaume Feliksdal, founder and co-owner of FELIXprinters. His background as engineer, industrial automation expert, automotive and robotics has served him well in the development and growth of the company in the last 10 years.

With the FELIX 3L we launched our first seriously tall printer. It is designed to print tall objects up to 400 mm, to offer huge possibilities when it comes to printing tall objects with great detail. You can imagine that the FELIXprinters headquarters was scattered with Eiffel Towers, Lady Liberties and other tall buildings and landmarks!

FELIX 1.0

Guillaume Feliksdal, founder and co-owner of FELIXprinters. His background as engineer, industrial automation expert, automotive and robotics has served him well in the development and growth of the company in the last 10 years.

2017 also saw a few new additions to the FELIXprinters product family.

The hugely popular FELIX Tec 4 was introduced to the market. This versatile work-horse answered the demand for a technically sound 3D printer that can print without hassle. It is a popular choice for educational institutions where a print-farm format is required.

The FELIX Pro 2 was also introduced and contained improvements from the first generation Pro.

FELIX 2.0

Reseller network

The FELIXprinters reseller network expanded beyond the Dutch borders very rapidly. Today, the product range is available via resellers on 5 continents with resellers providing on the ground support, service and repair.

FELIXprinters started with a completely different mission in mind. Founder Guillaume Feliksdal had the idea to build a humanoid walking robot. He decided to use 3D printing to produce the parts that he needed. At that stage in 2011, 3D printing was still in its infancy stage. He used a DIY 3D printer, but found that there was much room for improvement. This inspired him to build his own 3D printer. In his attic room in the evening hours after work, he created the first version. He named the printer with a play on words with his surname and the FELIX 1 was born.

Guillaume Feliksdal, founder and co-owner of FELIXprinters. His background as engineer, industrial automation expert, automotive and robotics has served him well in the development and growth of the company in the last 10 years.

By this time, 3D printing started to become more widely adopted as an industrial production method, used to make fixtures and tooling, implemented in creating production parts, for repair and jigs. FELIXprinters answered this development with its launch of the Pro L and XL in April 2019. These large-volume machines provide users the extra capacity needed for larger print items, with the reliability and ease-of-use allowing them to be seamlessly included in existing or new business activities.

Further developments led to the FELIX Pro 3. Read more about this key milestone here.

FELIXprinters started with a completely different mission in mind. Founder Guillaume Feliksdal had the idea to build a humanoid walking robot. He decided to use 3D printing to produce the parts that he needed. At that stage in 2011, 3D printing was still in its infancy stage. He used a DIY 3D printer, but found that there was much room for improvement. This inspired him to build his own 3D printer. In his attic room in the evening hours after work, he created the first version. He named the printer with a play on words with his surname and the FELIX 1 was born.

Guillaume Feliksdal, founder and co-owner of FELIXprinters. His background as engineer, industrial automation expert, automotive and robotics has served him well in the development and growth of the company in the last 10 years.

3D Bioprinting is developing at a rapid pace. Medical and scientific breakthroughs, assisted by 3D printing technology is a field that shows promise for solving problems related to health, science and biology.

FELIXprinters introduced the FELIX BIOprinter, able to print viscous materials, bioinks and cells with a powerful extrusion system.

FELIXprinters started with a completely different mission in mind. Founder Guillaume Feliksdal had the idea to build a humanoid walking robot. He decided to use 3D printing to produce the parts that he needed. At that stage in 2011, 3D printing was still in its infancy stage. He used a DIY 3D printer, but found that there was much room for improvement. This inspired him to build his own 3D printer. In his attic room in the evening hours after work, he created the first version. He named the printer with a play on words with his surname and the FELIX 1 was born.

Guillaume Feliksdal, founder and co-owner of FELIXprinters. His background as engineer, industrial automation expert, automotive and robotics has served him well in the development and growth of the company in the last 10 years.

Custom 3D printing solutions

Besides the full range of standard 3D printers in various sizes from desktop to extra large volume, FELIXprinters has produced fully automated print farms for established consumer-oriented customers.

These clients wished to implement future-proof entirely digital manufacturing process through the use of 3D printing was a step towards the creation of new designs and new products impossible or uneconomic using conventional production techniques.

FELIX 1.0

Guillaume Feliksdal, founder and co-owner of FELIXprinters. His background as engineer, industrial automation expert, automotive and robotics has served him well in the development and growth of the company in the last 10 years.

Video messages from some of our resellers

Video messages

Services

Our Story

We recommend and have preconfigured Simplify3D, the best slicing software available on the market. Several presets are programmed to get you started quickly. Simply adapt your project designs to suit your needs.

Special Deals

Our webshop

Our Blog Post

XPECT-INX Enters into Distribution Agreement with FELIXprinters

December 17, 2020

Biofabrication is the use of additive manufacturing or 3D printing technologies for the (re)generation of biological tissues. This scientific field has the potential to revolutionize modern …

FELIXprinters Announces Commercial Launch of the FELIX BIOprinter

March 10, 2020

After introducing its BIOprinter at the recent Formnext 2019 event in Frankfurt in November, FELIXprinters is delighted to announce that the machine is now commercially available, …

Major Success for

FELIXprinters

at Formnext

November 29, 2019

FELIXprinters capped off its busy show season (which included exhibiting at TCT 2019 in Birmingham, U.K.) with a hugely successful four days at the flagship Formnext …

Contact Information

zeemanlaan 15

3401 MV IJsselstein

the netherlands

Phone: +31 30 303 1387

email: info@felixprinters.com